PurAffin Chromatography

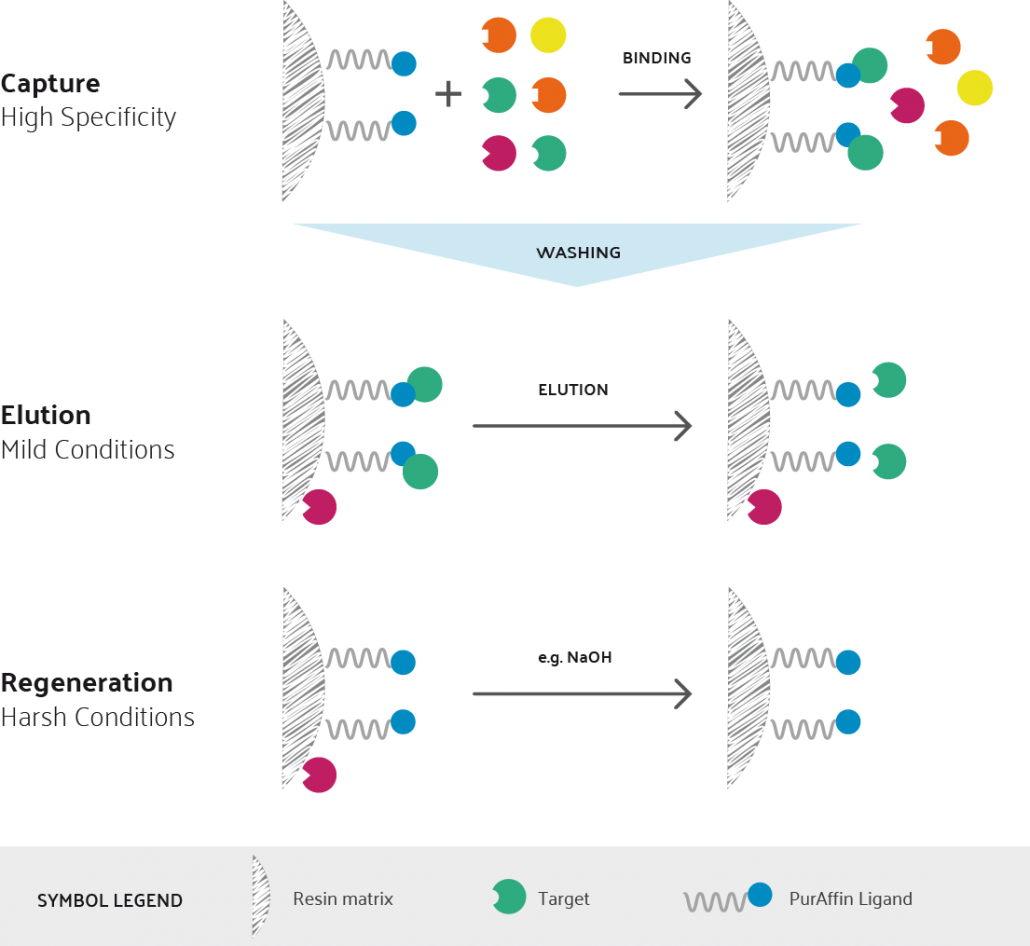

The PurAffin® technology was developed by 3B Pharmaceuticals to bring the advantages of peptide-based affinity separation products to the customer.

With PurAffin resins you can streamline your downstream process (DSP) development, improve the performance of complex processes, and thus reduce overall manufacturing cost.

Key advantages over classical non-affinity chromatography methods and antibody-based affinity purification methods are:

- Fully synthetic and stable affinity matrix

- Several hundred purification cycles per column

- Improved yield and purity

- Selective purification of the native target protein

- Option to generate process IP based on the affinity ligand

- Binding properties of PurAffin ligands can be fine-tuned to your specific process and target protein requirements

When should you consider custom development of PurAffin process steps for your DSP project?

PurAffin purification steps are particularly beneficial when…

- you are facing purification challenges involving closely related by-products, inactive protein fractions, insufficient yield or purity, or an unstable multi-column process.

- you need to remove a specific contaminant.

- a robust process platform is needed for biologics sharing a common scaffold, sequence region, or fusion partner (e.g. FC-Fusion, VLP, non-antibody binding protein).

- your antibody cannot be purified reliably with protein A/G.

A custom PurAffin ligand program should be started early in your DSP development in order to synchronize DSP and PurAffin development.

PurAffin is a registered trademark of 3B Pharmaceuticals GmbH.